Clever combinations of established individual systems

Our established gantries and feeders can be used in a variety of combinations and combined with a wide range of added units. We combine additional functions and units to create a system solution tailored precisely to your needs. Functions that can be integrated include feeding and discharge of material with our RoundTrack system, centring and separating units, vision systems for position detection and turning and reversing devices. Our systems are used in a wide variety of industries.

Applications

- Automation cells

- Production and assembly lines

- Machine loading and unloading

- Part transfer between and within machining and assembly stations

- Finished part removal, stacking and packaging

- Integration of handling components in existing production lines

The core benefits

- Highly dynamic processes

- Customized solutions

- Turnkey systems

- Intelligent software

- Low-maintenance components

- Expert project management

Examples of system solutions

|

System module kit |

Stacking of cut blanks |

Switch cabinet production |

Press automation with Front of Line |

|---|---|---|---|

|

|

|

|

|

Linear gantry |

x |

||

|

Area gantry |

x |

||

|

Traversing feeders |

x |

x |

|

|

Advanced configuration |

x |

x |

x |

|

Vision system |

x |

||

|

Line control system |

x |

x |

x |

|

Gripper system |

x |

x |

x |

|

RoundTrack system |

x |

x |

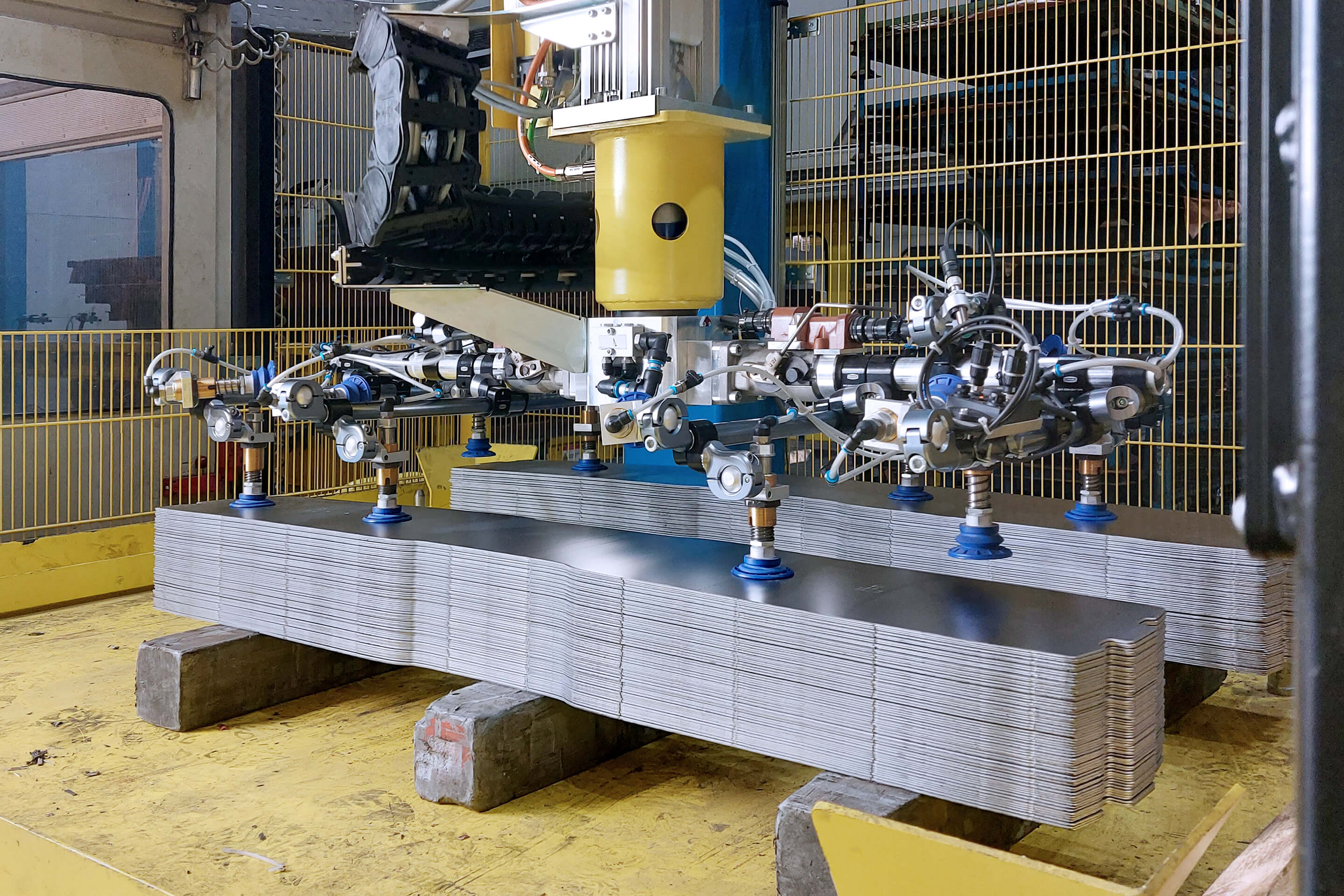

Stacking of cut blanks

Task

- Stacking cut blanks and flat formed parts starting in an undefined position precisely on pallets and in load carriers

The solution

- Expanding linear gantry SRLSM 2/040 to create an area gantry

- Additional rotary axis and vacuum gripper

- Position detection by integrated vision system

- Uninterrupted container change by integrated RoundTrack system and carriage with lifting function

- Intelligent process sequence with double pick function for optimized cycle times

Switch cabinet production

Task

- Feeding of blanks to a forming unit for switch cabinet doors

- Pick-up of blank stacks from an AGV

- Integration in fully automatic production environment with master computer

The solution

- Pick-up of pallets from an AGV by a chain conveyor

- Component handling with traversing feeders with additional axes

- Blank separation with the aid of universal tools equipped with blast nozzles

- Part centring including spray oil application in the forming areas

- Control system for the overall line

- Intelligent software with master computer connection

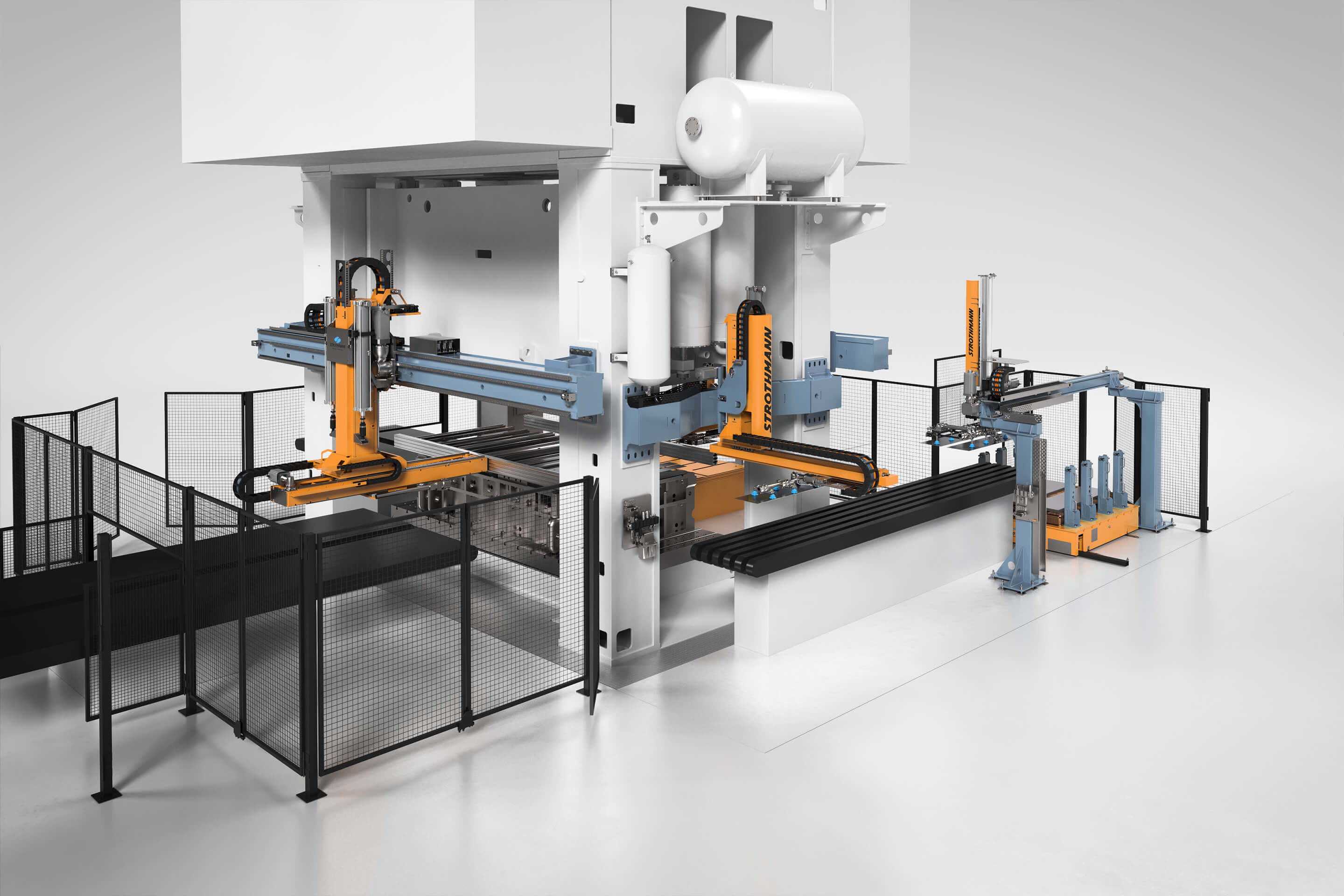

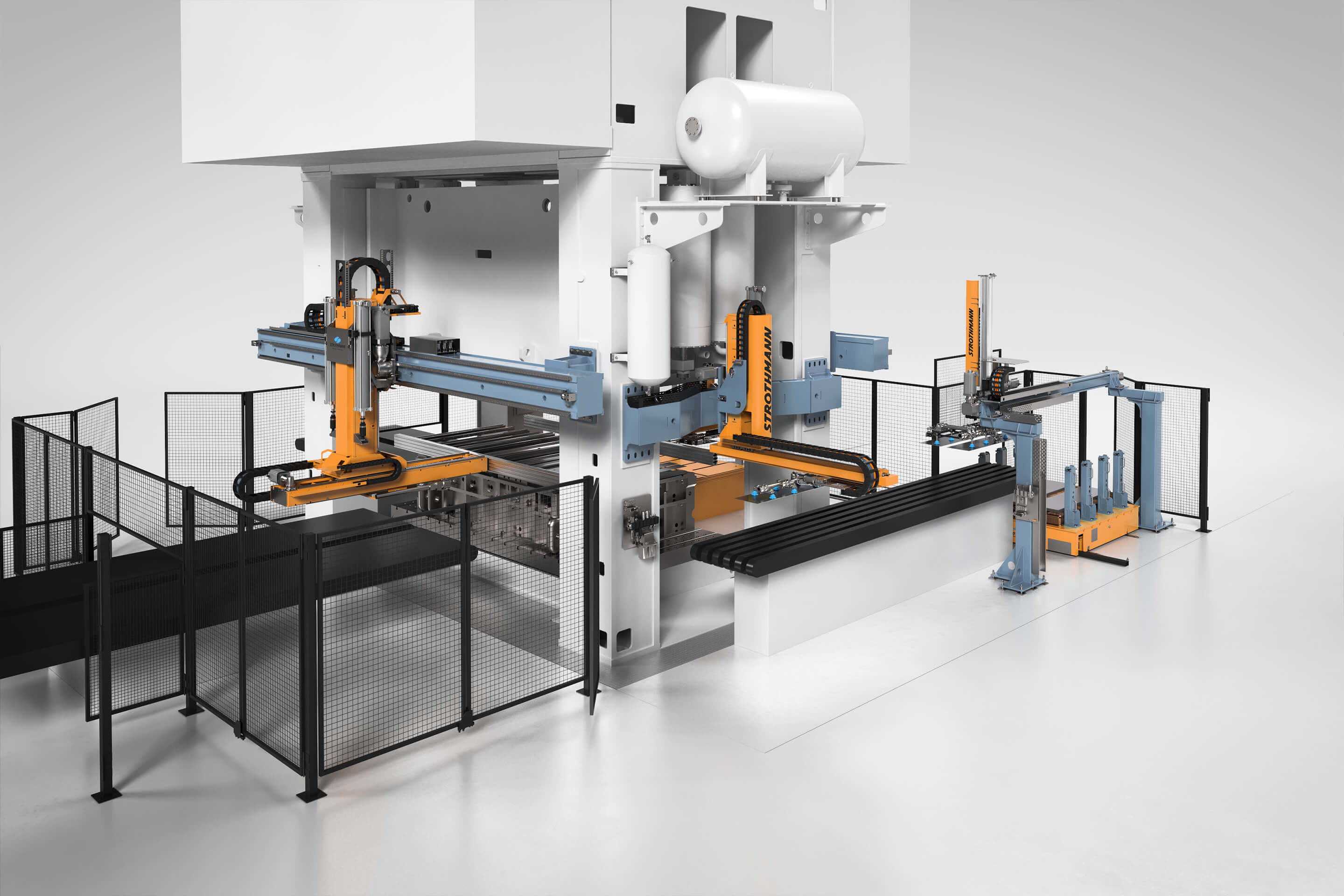

Press automation with Front of Line

Task

- Destacking of blank stacks, supply to and transport within a press

The solution

- Blank stack supply by carriages on the RoundTrack system

- Blank destacking by a linear gantry

- Blank separation by magnets and blast nozzles

- Traversing feeders in two sizes for material feeding and handling within the press

- Combined operating modes of the individual feeders with different throughfeed directions

- Control system for the overall line