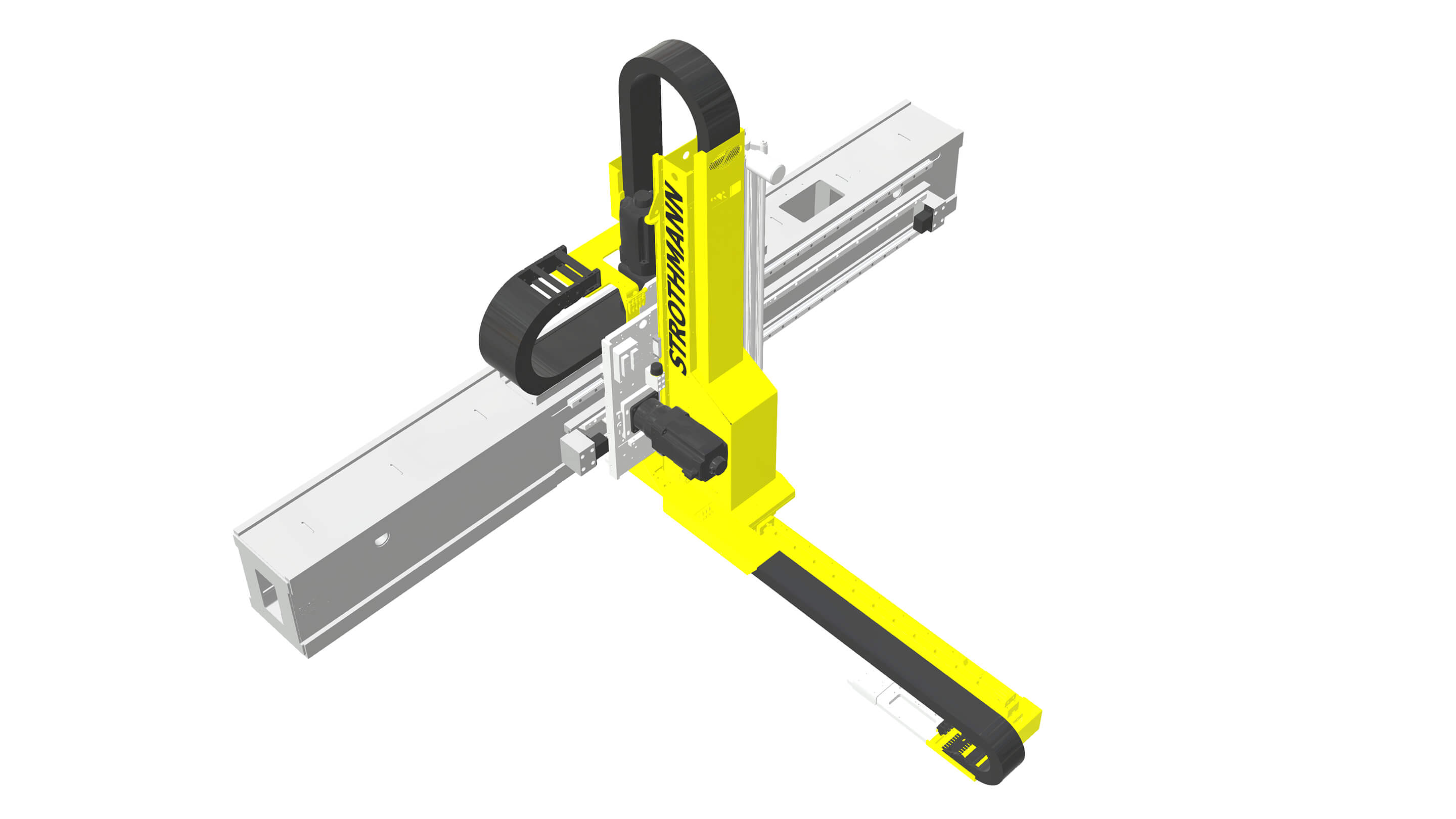

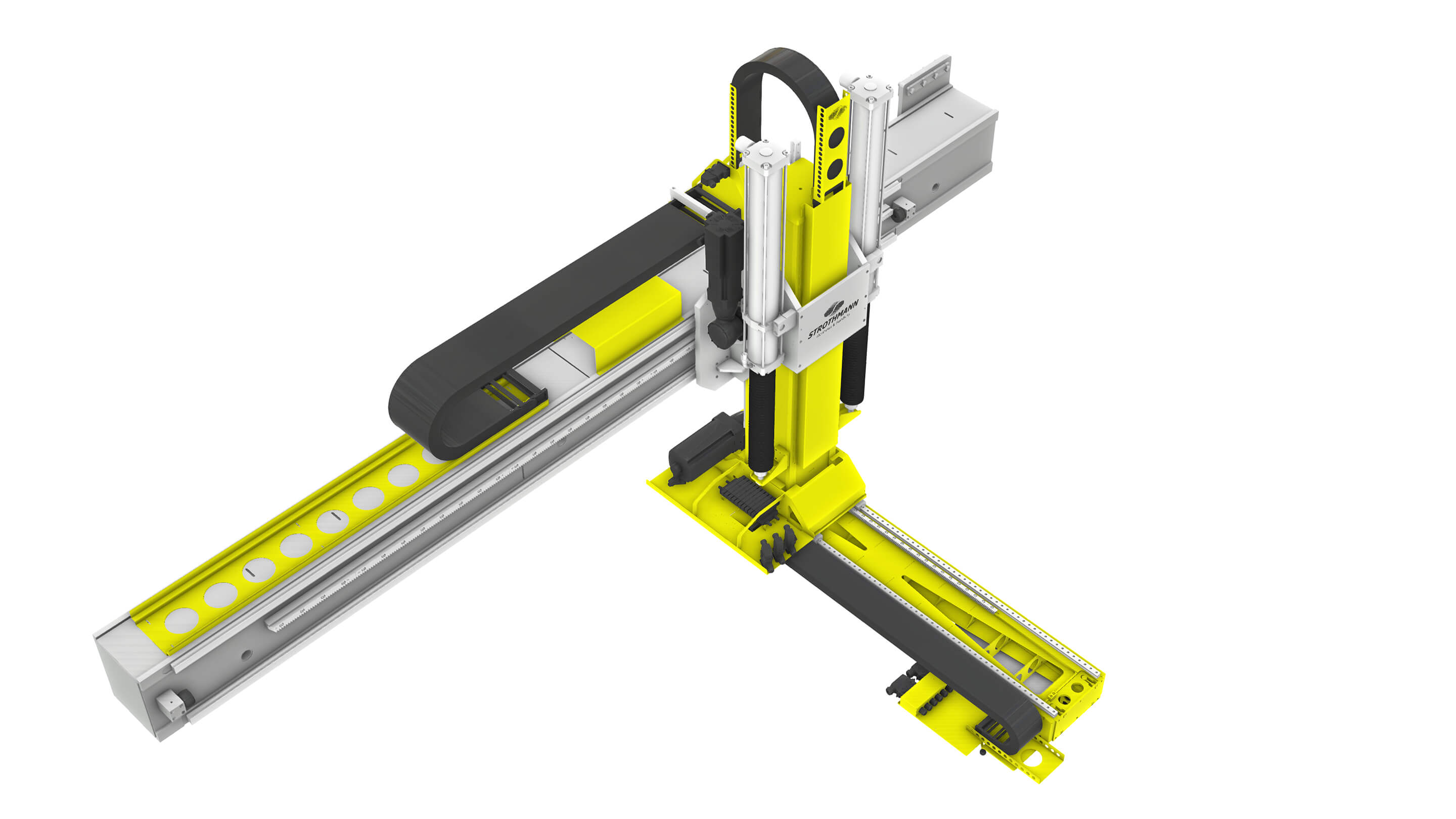

Highly dynamic feeder systems (transfer feeders)

Traversing feeders have three axes in the longitudinal, transverse and vertical direction. Overlaid movements ensure excellent dynamics in the feed axis. This can save a lot of time, particularly in loading processes.

Feeder systems of the SFT series

Numerous options, e.g. rotary axes or the combination of multiple feeder modules allow the feeder to be adapted perfectly to the specific customer applications. Extensive interfaces for actuators and sensor systems permit the use of a wide range of tools and end effectors.

Overview Traversing feeders

Series |

3/040 |

3/080 |

3/120 |

3/200 |

|---|---|---|---|---|

|

|

|

|

|

Load-bearing capacity |

40 – 100 kg |

60 – 200 kg |

120 – 250 kg |

200 – 350 kg |

Max. stroke X |

3300 mm |

4700 mm |

4500 mm |

6000 mm |

Max. stroke Y |

20000 mm |

20000 mm |

20000 mm |

20000 mm |

Max. stroke Z |

1000 mm |

1000 mm |

1100 mm |

1100 mm |

Max. speed X |

6 m/s |

6 m/s |

7 m/s |

7 m/s |

Max. speed Y |

1.5 m/s (3.5 m/s) |

1.5 m/s (3.5 m/s) |

1.5 m/s (4 m/s) |

1.5 m/s (4 m/s) |

Max. speed Z |

1.5 m/s |

1.5 m/s |

1.5 m/s |

1.5 m/s |

Max. acceleration X |

15 m/s² |

15 m/s² |

20 m/s² |

13.5 m/s² |

Max. acceleration Y |

7.5 m/s² (3.5 m/s²) |

7.5 m/s² (3.5 m/s²) |

7 m/s² (4 m/s²) |

6.5 m/s² (4 m/s²) |

Max. acceleration Z |

7.5 m/s² |

7.5 m/s² |

7.5 m/s² |

7.5 m/s² |

| Details | Details | Details | Details |

Additional applications feeder systems

FAQ: Frequently asked questions about Fedder systems or transfer feeders.

A feeder system offers several user benefits, especially in the manufacturing industry. Here are some examples:

Automated material supply: A feeder system automates the supply of materials, components or workpieces to a production process. This provides a continuous supply to machines or workstations and reduces the need for manual material handling. This increases productivity and reduces labor.

Efficient and reliable material feeding: Using a feeder system ensures efficient and reliable material feeding. The system can be configured to feed materials in a precise and consistent manner, improving the quality and consistency of manufactured products.

Reduced set-up times: A feeder system allows for quick changeover and adaptation to different materials or production requirements. This reduces set-up times and the system can respond flexibly to different materials or product variants. This leads to increased efficiency and reduced lead times.

Flexibility and adaptability: A feeder system can be adapted to different production requirements and material types. It can be equipped with different feeding mechanisms or customization options to enable optimal material feeding. This makes the system flexible and versatile.

Traversing feeders are used in various applications in the manufacturing industry:

Assembly and manufacturing lines: traversing feeders are often used in assembly and manufacturing lines to transport materials or components to the various work stations. They enable continuous material feeding along the line and ensure a smooth production process.

Packaging industry: In the packaging industry, traversing feeders are used to transport packaging materials such as cartons, totes or bags to the packaging machines. They ensure precise positioning of packaging materials and enable efficient packaging of products.

Food and beverage industry: Traversing feeders are used in the food and beverage industry, for example to feed ingredients or packaging materials to production lines. They ensure hygienic and controlled material feeding to guarantee the quality and safety of food products.

Automotive industry: Traversing feeders are used in the automotive industry to transport materials such as body components, vehicle interior parts or engine components to the relevant assembly stations. They enable precise positioning and an efficient work sequence in production.