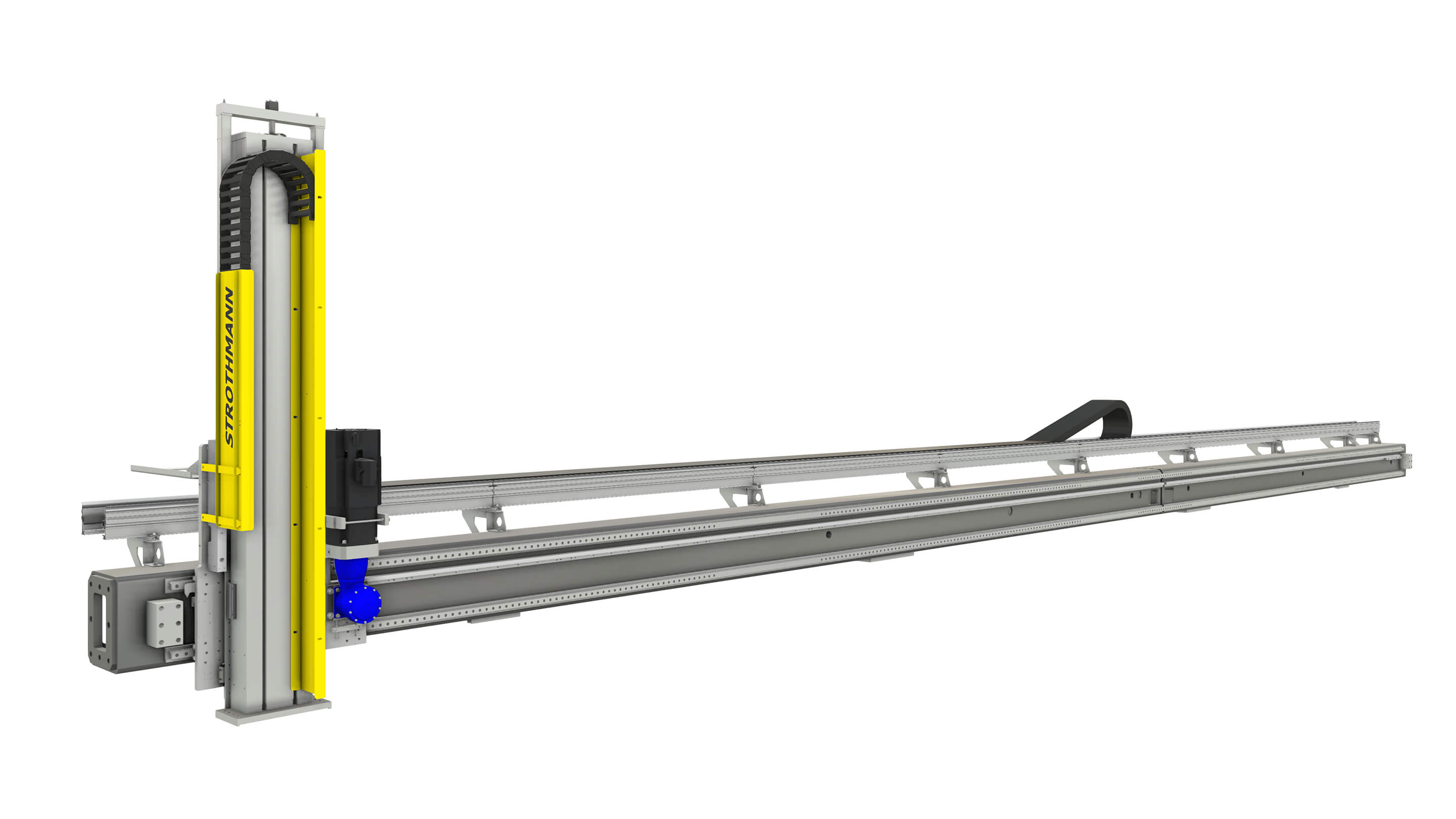

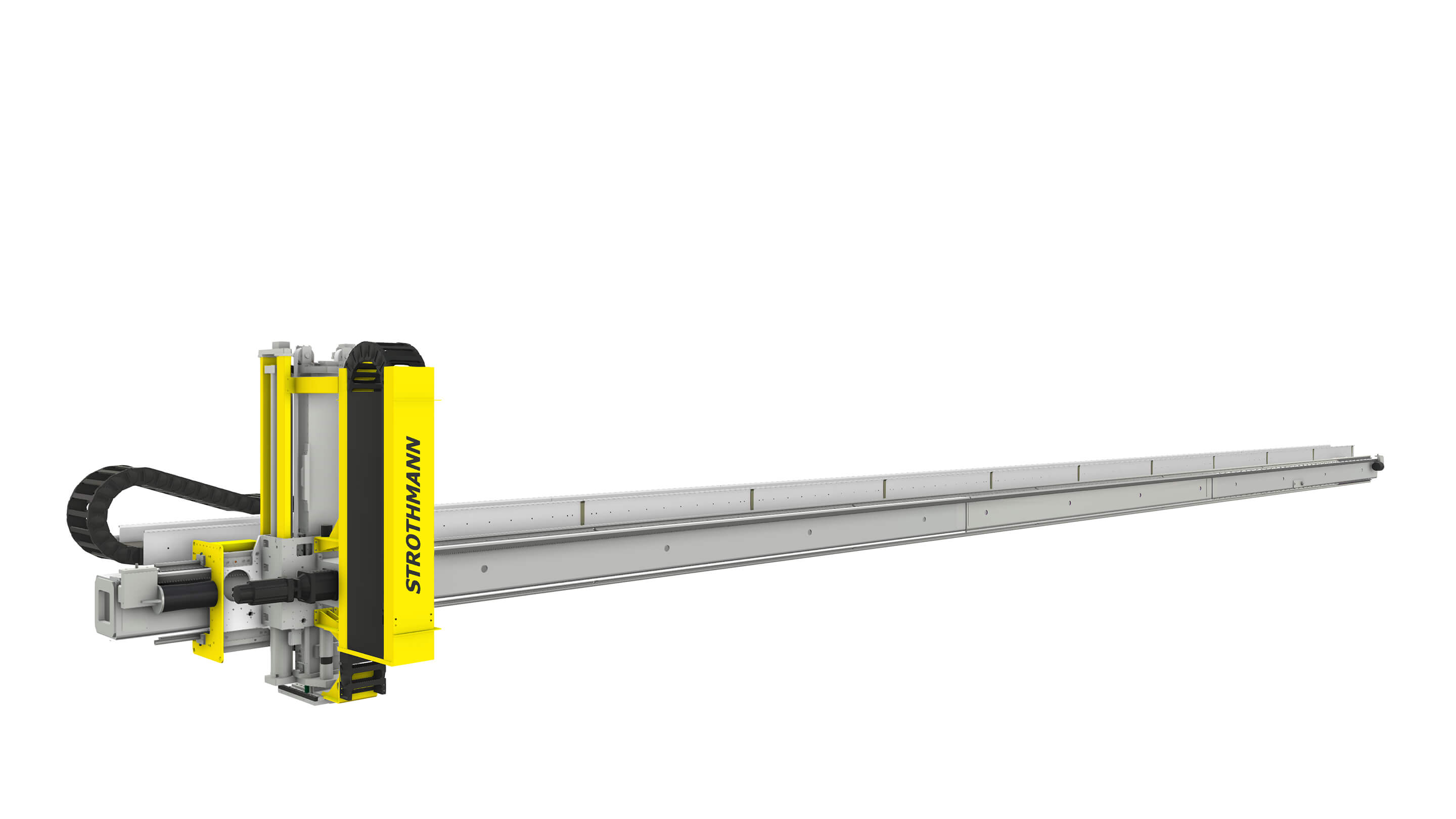

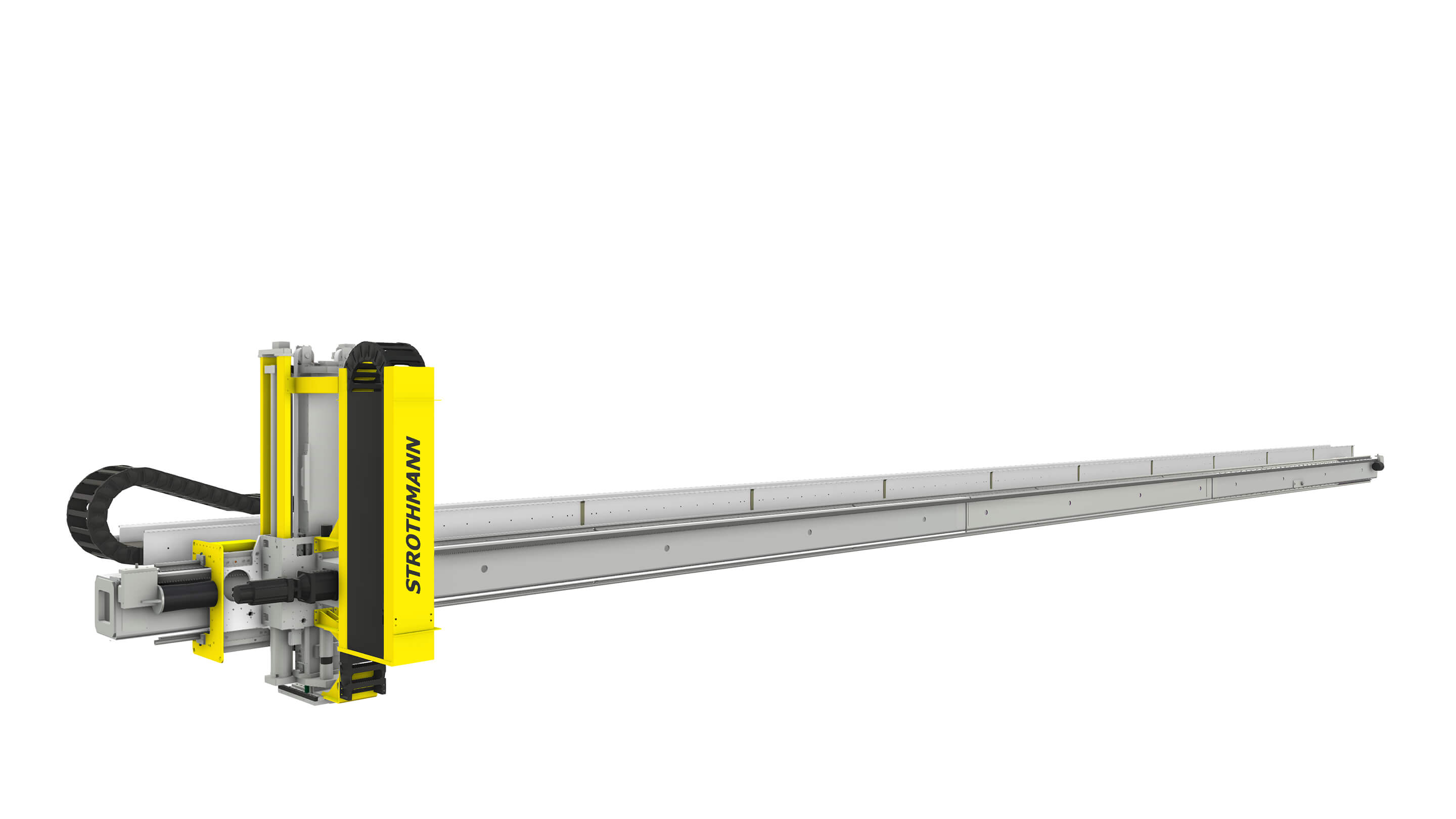

Universal Line gantries (two-axis gantries)

The two-axis line gantries of the SRL series are highly suitable for transporting loads in very constricted spaces. They are available with loading capacities ranging from 25 kg to 2000 kg.

Line gantries of the SRL series

Each series is available in two different performance classes: “heavy-duty” for maximum loading capacities with normal dynamics or “dynamic” for maximum acceleration at a normal loading capacity. Numerous options e.g. rotary axes or several slides on one axis can be added to tailor the linear gantry precisely to the customer’s requirements. Extensive interfaces for actuators and sensor systems permit the use of a wide range of grippers and end effectors.

System overview line gantries

Series |

2/020 |

2/040 |

2/120 |

2/400 |

2/900 |

|---|---|---|---|---|---|

|

|

|

|

|

|

Load-bearing capacity |

50 kg (25 kg) |

100 kg (50 kg) |

300 kg (150 kg) |

500 kg (250 kg) |

2000 kg (1000 kg) |

Max. stroke Y |

6400 mm |

Aluminium carrier: |

>50000 mm |

> 50000 mm |

> 50000 mm |

Max. stroke Z |

1500 mm |

1700 mm |

1700 mm |

2600 mm |

3000 mm |

Max. speed Y |

3 m/s |

3,75 m/s |

4,5 m/s |

3,2 m/s |

2,5 m/s |

Max. speed Z |

2 m/s |

2 m/s |

1,75 m/s |

1,5 m/s |

2 m/s |

Max. acceleration Y |

7,5 m/s² (10 m/s²) |

5 m/s² (10 m/s²) |

5 m/s² (10 m/s²) |

2,5 m/s² (5 m/s²) |

2,5 m/s² (5 m/s²) |

Max. acceleration Z |

5 m/s² (10 m/s²) |

5 m/s² (10 m/s²) |

5 m/s² (10 m/s²) |

2,5 m/s² (5 m/s²) |

2,5 m/s² (5 m/s²) |

Span |

4500 mm (3500 mm) |

Aluminium carrier: |

8000 mm (5500 mm) |

8000 mm |

on request |

Carrier structure |

Aluminium profile |

Aluminium profile or steel |

Steel |

Steel |

Steel |

| Details | Details | Details | Details | Details |

*Figures in brackets for performance class “dynamic”

Additional applications line gantries

FAQ: Frequently asked questions about line gantries (2-axis gantries)

Line gantries or 2-axis gantries offer a variety of user benefits in different areas. These can vary depending on the application and the requirements. Examples:

Precise positioning: 2-axis gantries enable precise positioning of workpieces or tools along two axes. This is particularly useful in the manufacturing industry, for example when milling, cutting or engraving materials.

High flexibility: By using 2-axis gantries, different types of tasks can be performed as they allow movement along two axes. This makes them versatile in various industries such as automation, packaging or woodworking.

Improved productivity: The use of 2-axis gantries can increase productivity as they allow fast and precise movements. This can speed up work processes and shorten lead times.

Space savings: Compared to multi-axis robotic systems or complex machines, 2-axis gantries require less space. They are compact and can be used in working environments with limited space.

Cost efficiency: 2-axis gantries can be a cost-effective solution, especially for applications that do not require complex motion patterns. They are often less expensive than fully multi-axis systems and can still effectively perform the required tasks.

Line gantries are used in a wide variety of applications, especially in the manufacturing and automation industries. Examples:

Assembly: Line gantries are often used in assembly processes to precisely position and assemble workpieces or components along a line. This can be the case, for example, in the automotive industry when assembling components or in the electronics industry when assembling printed circuit boards.

Material handling: Line gantries are used for automated handling of materials along a line. This can include transporting materials from one station to the next or loading and unloading machines. Examples include the logistics industry, packaging applications or the food industry.

Quality control: In quality control, line gantries are used to move workpieces or products along a line and perform various tests or inspections. This enables fast and precise monitoring of product quality and sorting out of defective products.

Packaging: Line gantries are used in the packaging industry to position, stack or pack products along a line. For example, they can be used in food processing to fill products into containers or seal packages.

Labeling and marking: Line gantries can be used in applications where accurate labeling or marking of products along a line is required. This may be the case in the pharmaceutical industry, the cosmetics industry or in the production of packaging.